Your Concrete slab manufacturing process images are available in this site. Concrete slab manufacturing process are a topic that is being searched for and liked by netizens today. You can Get the Concrete slab manufacturing process files here. Download all free images.

If you’re looking for concrete slab manufacturing process pictures information related to the concrete slab manufacturing process keyword, you have visit the ideal blog. Our site always provides you with hints for viewing the maximum quality video and image content, please kindly hunt and find more enlightening video articles and images that match your interests.

Concrete Slab Manufacturing Process. Pour Compact and. Concrete production can create pollution mainly in the form of dust and noise. The formwork shall be designed to withstand construction loads such as fresh. Assemble and Erect Formwork for Slab.

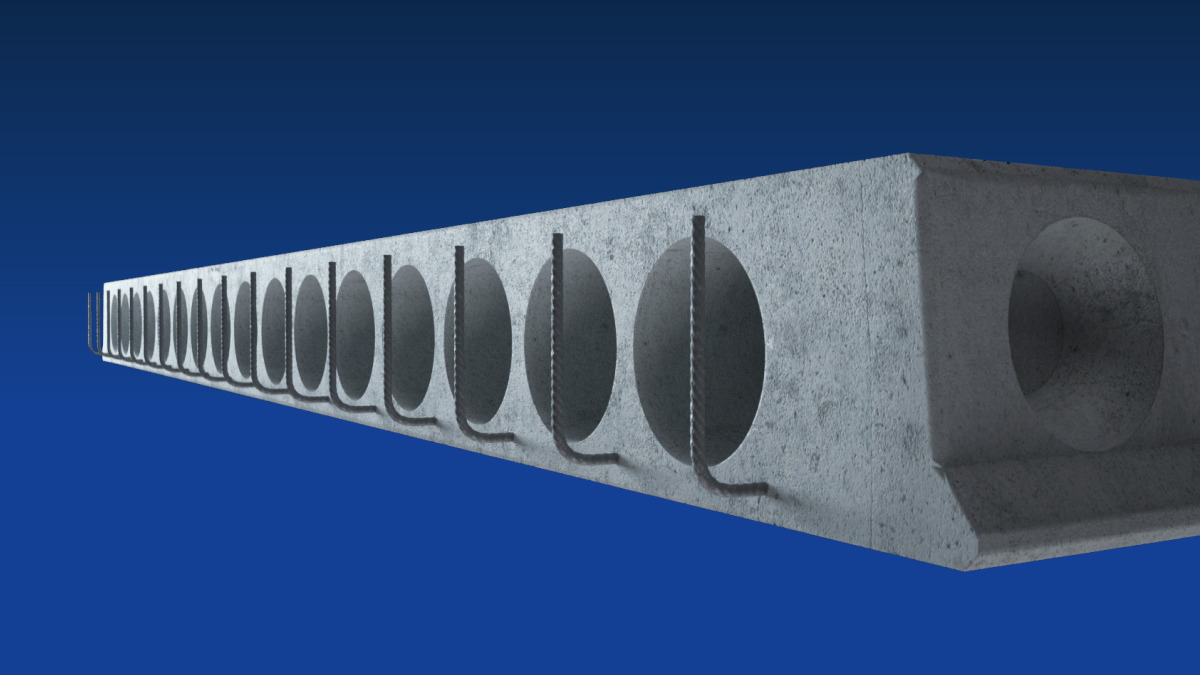

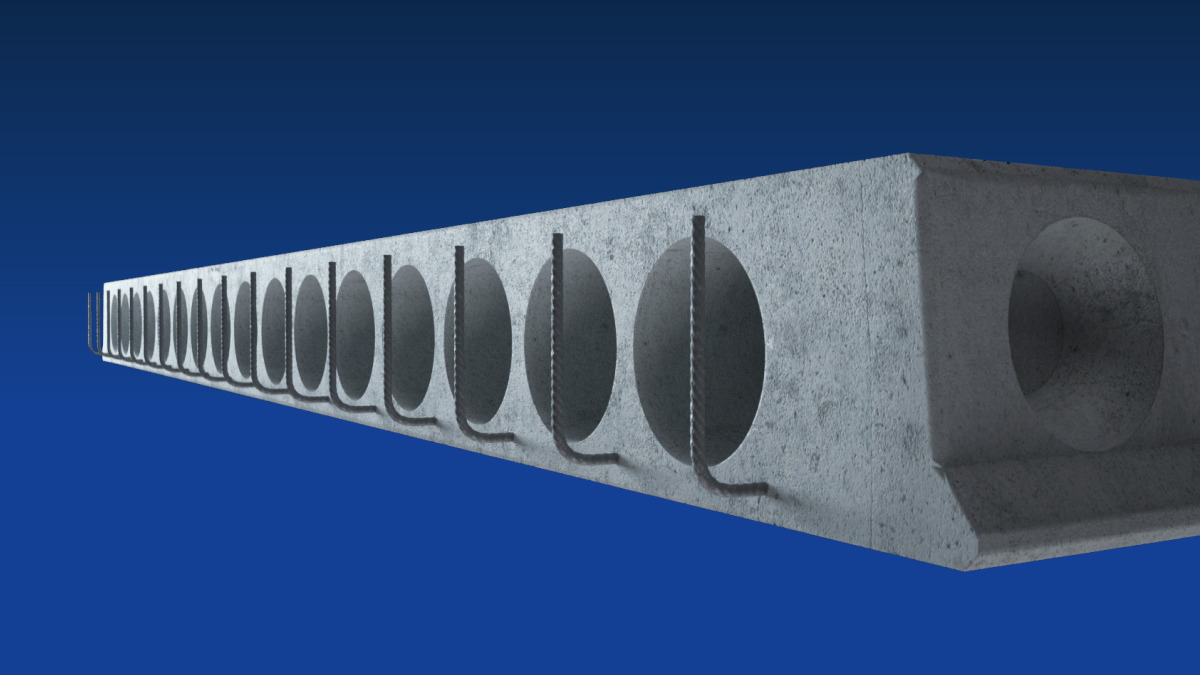

New Manufacturing Method For Prestressed Hollow Core Slabs Concrete Plant Precast Technology From bft-international.com

New Manufacturing Method For Prestressed Hollow Core Slabs Concrete Plant Precast Technology From bft-international.com

Concrete Floor Slab Construction Process 1. A wet press process typically involves introducing a highly fluid concrete mix into a mold 1012 applying hydraulic pressure to consolidate the concrete eg 1000-3000 PSI and to extract excess water removing the pressed concrete 16 while in a green state from the mold 1012 and then standing the slab 16 units immediately upon removal from the mold 1012. Formwork construction shall be designed to withstand concrete loads such as the fresh concrete pressures weights of. Batching or measureme nt of materials 2. However no matter how basic or complex the floor is the construction method is similar and includes. Floor slabs can range from a simple residential basement slab to a heavy-duty industrial floor.

For this the mould frame has to be sealed hermetically with the lower surface face plate.

Pour Compact and. The result is a two-layer slab. Concrete production can create pollution mainly in the form of dust and noise. The advantage of this method is that it gives concrete slab manufacturers great creative freedom. First a mold is. Saw blades can be cooled with water that can be filtered and reused.

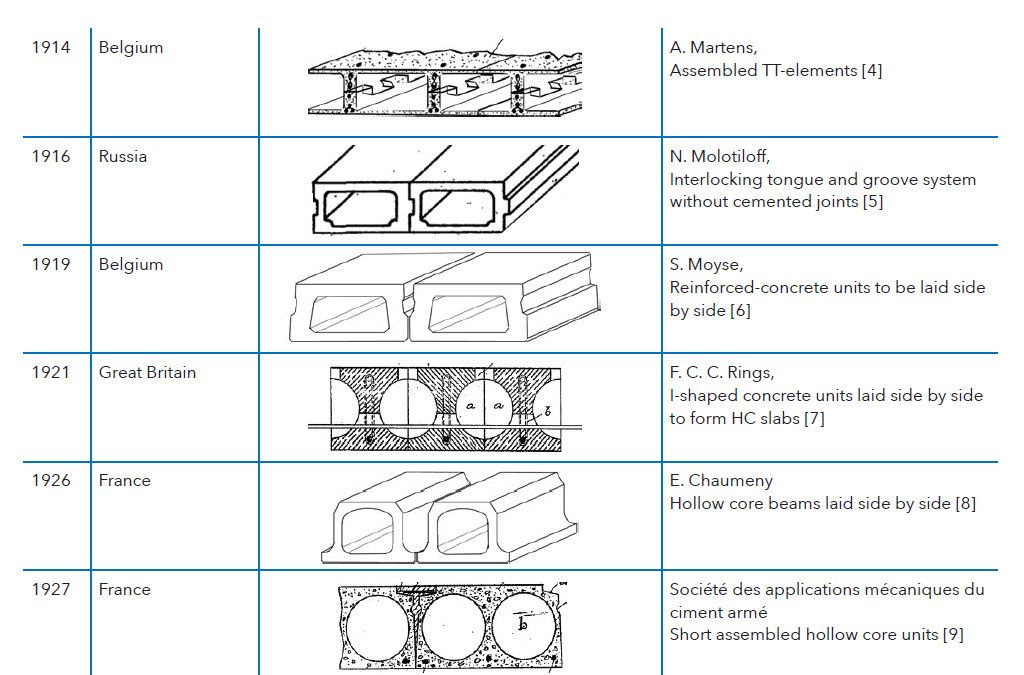

Source: researchgate.net

Source: researchgate.net

Readymade concrete slab making process in india. Concrete Floor Slab Construction Process 1. The formwork shall be designed to withstand construction loads such as fresh. First a mold is. The first layer is rather liquid when it is filled into the mould.

Source: youtube.com

Source: youtube.com

Concrete production can create pollution mainly in the form of dust and noise. When the concrete is hard the attachments of the parts at the joint is loosened so that the tension originally applied to the short parts is now at least partly applied to the concrete. For this the mould frame has to be sealed hermetically with the lower surface face plate. The first layer is rather liquid when it is filled into the mould. Pour Compact and.

Source: hollowcore.org

Source: hollowcore.org

Batching or measureme nt of materials 2. Floor slabs can range from a simple residential basement slab to a heavy-duty industrial floor. The stages of concrete production are. Readymade concrete slab making process in india. Pour Compact and.

Source: pinterest.com

Source: pinterest.com

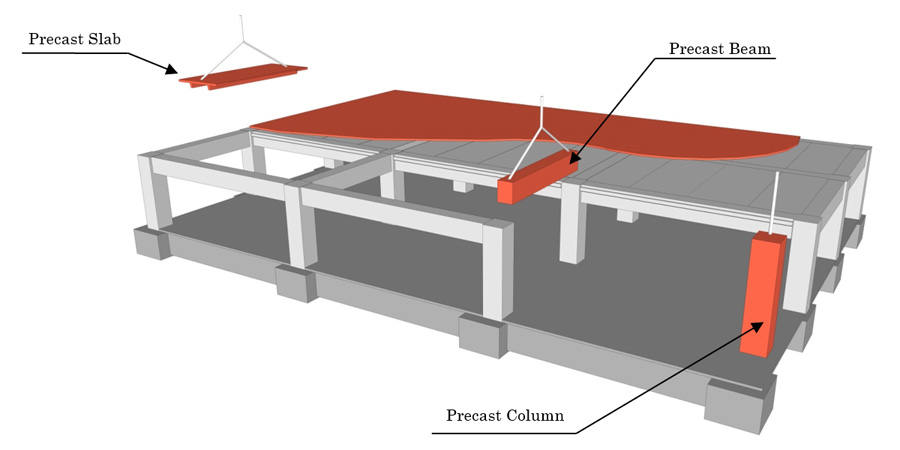

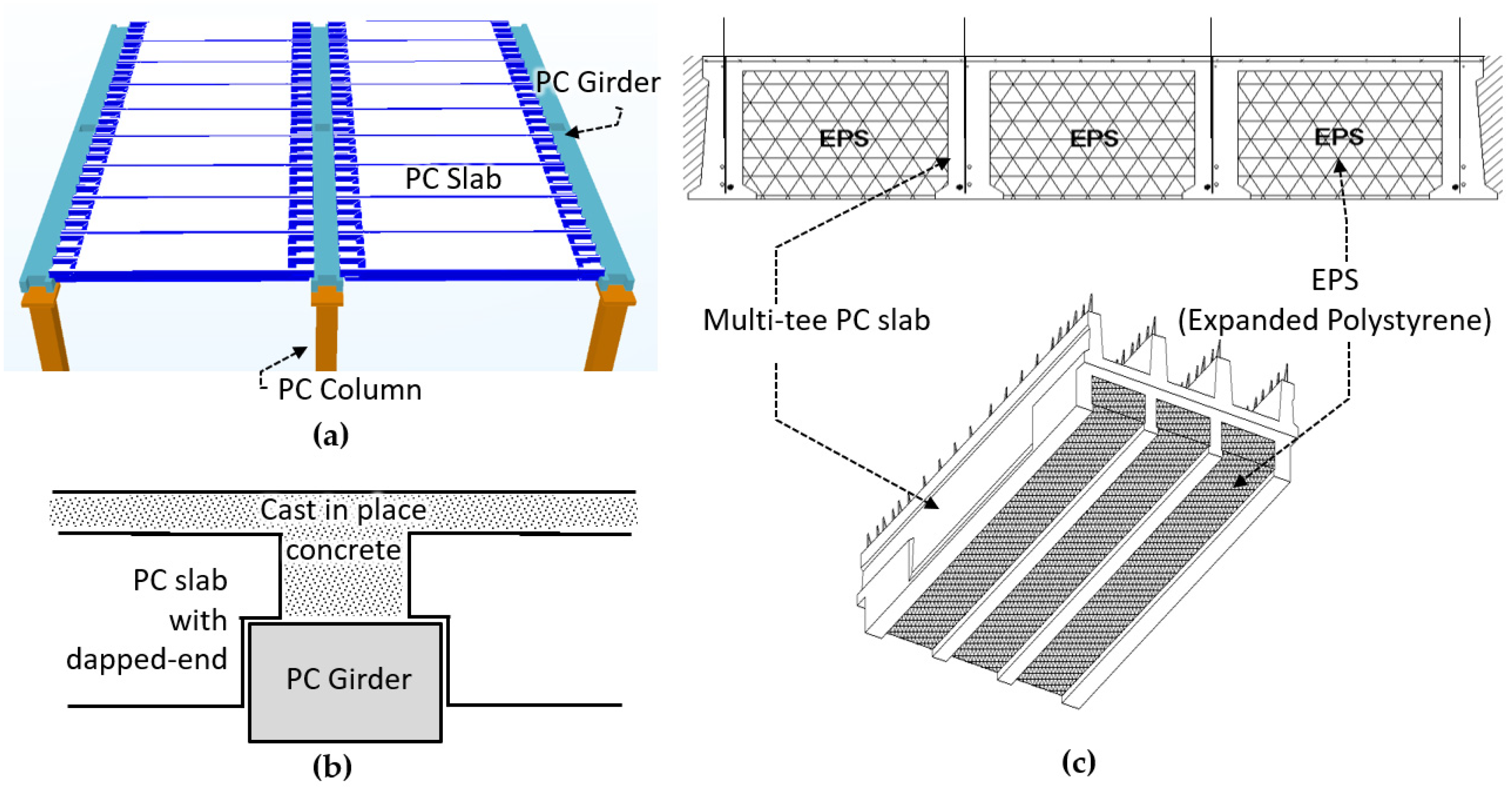

For this the mould frame has to be sealed hermetically with the lower surface face plate. However no matter how basic or complex the floor is the construction method is similar and includes. Preparing the sub-grade and sub-base placing the reinforcement and. Saws can be encased in noise absorbing containers. The following figures illustrate the precast concrete process.

Source: researchgate.net

Source: researchgate.net

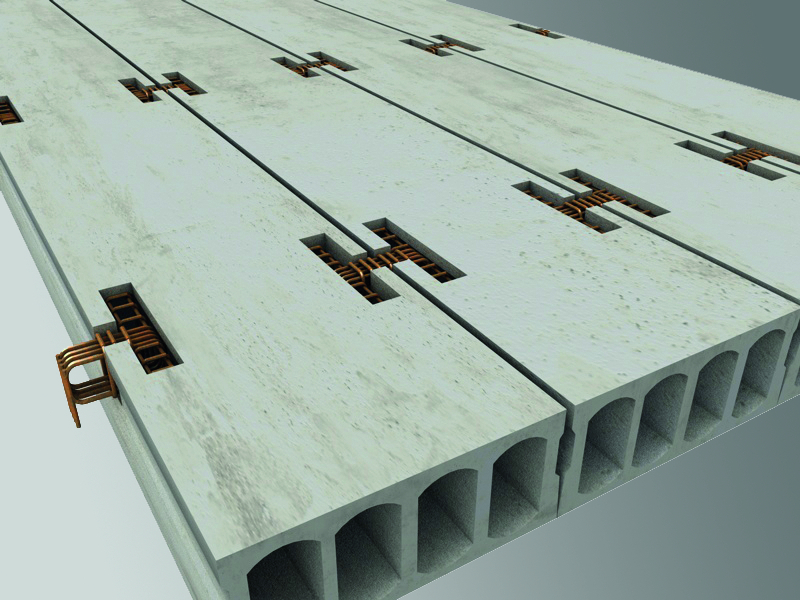

Production of reinforced cages and main connections. The formwork shall be designed to withstand construction loads such as fresh. This is what gives this method its name. Readymade concrete slab making process in india. Pour Compact and.

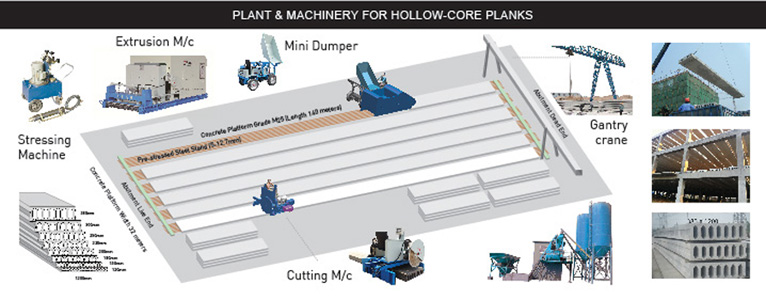

Source: m.made-in-china.com

Source: m.made-in-china.com

For this the mould frame has to be sealed hermetically with the lower surface face plate. The concrete slab production process is based on the compaction of concrete utilizing hydraulic pressing. The result is a two-layer slab. Slab manufacturing plants WEGH Group designs and builds complete plants for the manufacture of all prefab elements that make up ballastless railway tramway and underground superstructures such as for instance the prestressed reinforced concrete slab tracks used in the Arianna system. Concrete production can create pollution mainly in the form of dust and noise.

Source: orsc.co.jp

Source: orsc.co.jp

The stages of concrete production are. Preparing the sub-grade and sub-base placing the reinforcement and. Readymade concrete slab making process in india. The precast factory often has specialist workshops for the manufacture and maintenance of moulds and for the production of jig-built reinforcing cages and connections. The following figures illustrate the precast concrete process.

Source: keeganprecast.com

Source: keeganprecast.com

For instance it needs. Pour Compact and. In addition there are numerous construction elements that have to be considered in the course of the construction of. Saws can be encased in noise absorbing containers. Readymade concrete slab making process in india.

Source: indiaprecast.com

Source: indiaprecast.com

Readymade concrete slab making process in india. However no matter how basic or complex the floor is the construction method is similar and includes. The first layer is rather liquid when it is filled into the mould. Concrete Floor Slab Construction Process 1. Formwork construction shall be designed to withstand concrete loads such as the fresh concrete pressures weights of.

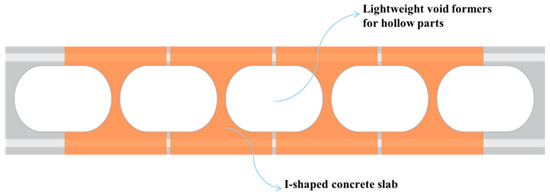

Source: mdpi.com

Source: mdpi.com

Formwork construction shall be designed to withstand concrete loads such as the fresh concrete pressures weights of. Slab manufacturing plants WEGH Group designs and builds complete plants for the manufacture of all prefab elements that make up ballastless railway tramway and underground superstructures such as for instance the prestressed reinforced concrete slab tracks used in the Arianna system. For this the mould frame has to be sealed hermetically with the lower surface face plate. Assemble and Erect Formwork for Slab. In this procedure two concrete layers are filled into the Masa slab press successively and compacted in a mould.

Source: bft-international.com

Source: bft-international.com

The following figures illustrate the precast concrete process. Slab jacking is a process that concrete contractors use to fill the space under the slab with a grout mixture that causes it to lift on the side that is sinking. In this procedure two concrete layers are filled into the Masa slab press successively and compacted in a mould. This is what gives this method its name. Slab manufacturing plants WEGH Group designs and builds complete plants for the manufacture of all prefab elements that make up ballastless railway tramway and underground superstructures such as for instance the prestressed reinforced concrete slab tracks used in the Arianna system.

Source: researchgate.net

Source: researchgate.net

In the hermetic pressing method two concrete layers are compacted hydraulically. The concrete slab production process is based on the compaction of concrete utilizing hydraulic pressing. Prior to the placement of reinforcement for concrete floor slab. Pour Compact and. Production of reinforced cages and main connections.

Source: m.made-in-china.com

Source: m.made-in-china.com

The advantage of this method is that it gives concrete slab manufacturers great creative freedom. Readymade concrete slab making process in india. Floor slabs can range from a simple residential basement slab to a heavy-duty industrial floor. Concrete production can create pollution mainly in the form of dust and noise. First a mold is.

Source: m.made-in-china.com

Source: m.made-in-china.com

The wet press process is used for making paver units concrete slabs flags and curb kerb stones as well as other shaped objects. The first layer is rather liquid when it is filled into the mould. Production of reinforced cages and main connections. Assemble and Erect Formwork for Slab. In this procedure two concrete layers are filled into the Masa slab press successively and compacted in a mould.

Source: lceted.com

Source: lceted.com

The result is a two-layer slab. The stages of concrete production are. Saws can be encased in noise absorbing containers. Slab jacking is a process that concrete contractors use to fill the space under the slab with a grout mixture that causes it to lift on the side that is sinking. In the hermetic pressing method two concrete layers are compacted hydraulically.

Source: hollowcore.org

Source: hollowcore.org

Concrete production can create pollution mainly in the form of dust and noise. The concrete slab production process is based on the compaction of concrete utilizing hydraulic pressing. The formwork shall be designed to withstand construction loads such as fresh. Prepare and Place Reinforcement for Slab. The wet press process is used for making paver units concrete slabs flags and curb kerb stones as well as other shaped objects.

Source: mdpi.com

Source: mdpi.com

Readymade concrete slab making process in india. Assemble and Erect Formwork for Slab. In this procedure two concrete layers are filled into the Masa slab press successively and compacted in a mould. The wet press process is used for making paver units concrete slabs flags and curb kerb stones as well as other shaped objects. Slab manufacturing plants WEGH Group designs and builds complete plants for the manufacture of all prefab elements that make up ballastless railway tramway and underground superstructures such as for instance the prestressed reinforced concrete slab tracks used in the Arianna system.

Source: hollowcore.org

Source: hollowcore.org

In the hermetic pressing method two concrete layers are compacted hydraulically. In addition there are numerous construction elements that have to be considered in the course of the construction of. Saws can be encased in noise absorbing containers. Concrete production can create pollution mainly in the form of dust and noise. The first layer is rather liquid when it is filled into the mould.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title concrete slab manufacturing process by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.