Your Curing period of concrete slab images are ready in this website. Curing period of concrete slab are a topic that is being searched for and liked by netizens now. You can Find and Download the Curing period of concrete slab files here. Find and Download all royalty-free vectors.

If you’re searching for curing period of concrete slab pictures information connected with to the curing period of concrete slab keyword, you have visit the ideal site. Our site frequently gives you suggestions for seeing the maximum quality video and picture content, please kindly hunt and locate more informative video content and images that fit your interests.

Curing Period Of Concrete Slab. Curing concrete slab by ponding. Refer to Kosmatka et al. When outdoor temperatures are below 20 degrees Fahrenheit it is best to simply abandon the idea of placing concrete in outdoor locations since hydration stops completely at such temperatures. Made with SCMs may especially benefit from extended curing.

Curing Of Concrete Curing Time Duration Methods Of Curing Purpose Concrete Curing Grade Of Concrete Concrete Mix Design From in.pinterest.com

Curing Of Concrete Curing Time Duration Methods Of Curing Purpose Concrete Curing Grade Of Concrete Concrete Mix Design From in.pinterest.com

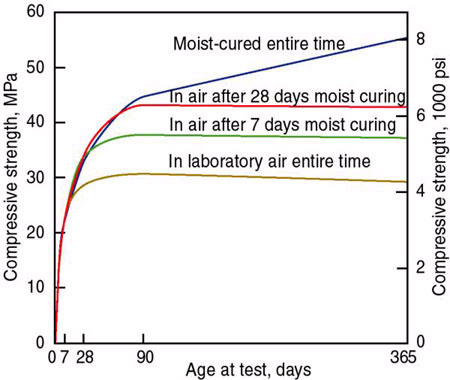

Concrete in cold weather absolutely does need to be curedthe surface can dry out even faster than in warm weather if the concrete is warmer than the air. The resistance of air-entrained concrete to freeze-thaw cycles and deicers is greatly enhanced by an air-drying period after initial moist curing. Watch the animation to learn how Bio-San C500s robust dual technology system eliminates the problem. Continue reading Top 16 Mistakes. Concrete installation is not nearly as straightforward as it seems. ACI 301 recommends a minimum curing period comparable to concrete attaining 70 of the specified compressive strength.

Here is advice for curing concrete in freezing temperatures.

Final curing shall be done by ponding and stacking water for minimum period of 7 days. Concrete in cold weather absolutely does need to be curedthe surface can dry out even faster than in warm weather if the concrete is warmer than the air. When outdoor temperatures are below 20 degrees Fahrenheit it is best to simply abandon the idea of placing concrete in outdoor locations since hydration stops completely at such temperatures. Our team of industry experts provides service and support that make working with us easy. Concrete installation is not nearly as straightforward as it seems. Final curing shall be done by ponding and stacking water for minimum period of 7 days.

Source: pinterest.com

Source: pinterest.com

Made with SCMs may especially benefit from extended curing. Done properly concrete poured in cool weather is actually stronger than concrete poured in hot weather thanks to the slow curing period. ACI 301 recommends a minimum curing period comparable to concrete attaining 70 of the specified compressive strength. Concrete installation is not nearly as straightforward as it seems. The need for adequate curing of concrete cannot be overemphasized.

Source: in.pinterest.com

Source: in.pinterest.com

The primary focus when curing a slab is to prevent shrinkage cracks related to loss of water due to evaporation. The need for adequate curing of concrete cannot be overemphasized. Everything from the mix design quantity of concrete to purchase site preparation tools weather forecast placement process form removal and curing process need to be. Our team of industry experts provides service and support that make working with us easy. When the temperature is pr edicted to be below 32F water curing is not recommended unless the.

Source: pinterest.com

Source: pinterest.com

Concrete should not be subjected to hydrostatic pressure during the initial curing period. Concrete installation is not nearly as straightforward as it seems. For over a century Euclid Chemical has built a reputation on quality products innovation and putting people first. If the air is below or expected to go below 40F then use cold weather techniques. Xypex Bio-San C500 is a uniquely designed admixture for integral long-term protection of concrete in harsh sewage conditions with high levels of H 2 S that cause Microbial Induced Corrosion MIC.

Source: researchgate.net

Source: researchgate.net

Euclid Chemical is a world leading manufacturer of specialty chemical products for the concrete and masonry construction industry. Our team of industry experts provides service and support that make working with us easy. Concrete installation is not nearly as straightforward as it seems. Be sure to keep the reinforcement mesh and rebar at the height specified by the engineer. In addition the concrete must be kept at a temperature greater than 10C for the three-day curing period following its installation to ensure correct strength and surface finish without frost damage.

Source: pinterest.com

Source: pinterest.com

Casting concrete slab is considerably crucial task in building construction and requires great planning and accuracy in addition to proper execution sequence. Concrete should not be subjected to hydrostatic pressure during the initial curing period. Xypex Bio-San C500 is a uniquely designed admixture for integral long-term protection of concrete in harsh sewage conditions with high levels of H 2 S that cause Microbial Induced Corrosion MIC. Be sure to keep the reinforcement mesh and rebar at the height specified by the engineer. When you are ready to begin pouring the concrete.

Source: theconstructor.org

Source: theconstructor.org

Final curing shall be done by ponding and stacking water for minimum period of 7 days. Concrete should not be subjected to hydrostatic pressure during the initial curing period. Curing concrete slab by ponding. This is generally the result of an issue with the curing of the concrete and cannot be controlled by the homeowner. Concrete installation is not nearly as straightforward as it seems.

Source: specialties.bayt.com

Source: specialties.bayt.com

This is generally the result of an issue with the curing of the concrete and cannot be controlled by the homeowner. There is a wealth of preparation that occurs before a single drop of concrete is ever poured onto the site. Subsequently since fresh concrete is critically saturated a drying period must occur after curing and before the concrete is exposed to freezing temperatures. Curing concrete slab by ponding. If the air is below or expected to go below 40F then use cold weather techniques.

Source: engr.psu.edu

Source: engr.psu.edu

Casting concrete slab is considerably crucial task in building construction and requires great planning and accuracy in addition to proper execution sequence. Made with SCMs may especially benefit from extended curing. For over a century Euclid Chemical has built a reputation on quality products innovation and putting people first. Our team of industry experts provides service and support that make working with us easy. If the air is below or expected to go below 40F then use cold weather techniques.

Source: in.pinterest.com

Source: in.pinterest.com

Typically this target is obtained within 7 days but it varies from mix to mix. Subsequently since fresh concrete is critically saturated a drying period must occur after curing and before the concrete is exposed to freezing temperatures. Curing has a strong influence on the properties of hardened concrete. Curing is the maintenance of a satisfactory moisture con-tent and temperature in concrete for a period of time imme-diately following placing and finishing so that the desired properties may develop Fig. Concrete in cold weather absolutely does need to be curedthe surface can dry out even faster than in warm weather if the concrete is warmer than the air.

Source: pinterest.com

Source: pinterest.com

In addition the concrete must be kept at a temperature greater than 10C for the three-day curing period following its installation to ensure correct strength and surface finish without frost damage. There is a wealth of preparation that occurs before a single drop of concrete is ever poured onto the site. Final curing shall be done by ponding and stacking water for minimum period of 7 days. Done properly concrete poured in cool weather is actually stronger than concrete poured in hot weather thanks to the slow curing period. Casting concrete slab is considerably crucial task in building construction and requires great planning and accuracy in addition to proper execution sequence.

![]() Source: biordiconcretes.com

Source: biordiconcretes.com

Our team of industry experts provides service and support that make working with us easy. Made with SCMs may especially benefit from extended curing. Everything from the mix design quantity of concrete to purchase site preparation tools weather forecast placement process form removal and curing process need to be. Subsequently since fresh concrete is critically saturated a drying period must occur after curing and before the concrete is exposed to freezing temperatures. When you are ready to begin pouring the concrete.

When the temperature is pr edicted to be below 32F water curing is not recommended unless the. The need for adequate curing of concrete cannot be overemphasized. When you are ready to begin pouring the concrete. If the air is below or expected to go below 40F then use cold weather techniques. Concrete installation is not nearly as straightforward as it seems.

Source: gharpedia.com

Source: gharpedia.com

Euclid Chemical is a world leading manufacturer of specialty chemical products for the concrete and masonry construction industry. Curing has a strong influence on the properties of hardened concrete. Refer to Kosmatka et al. Our team of industry experts provides service and support that make working with us easy. Casting concrete slab is considerably crucial task in building construction and requires great planning and accuracy in addition to proper execution sequence.

Source: concretedecor.net

Source: concretedecor.net

Everything from the mix design quantity of concrete to purchase site preparation tools weather forecast placement process form removal and curing process need to be. Everything from the mix design quantity of concrete to purchase site preparation tools weather forecast placement process form removal and curing process need to be. Watch the animation to learn how Bio-San C500s robust dual technology system eliminates the problem. Be sure to keep the reinforcement mesh and rebar at the height specified by the engineer. When the temperature is pr edicted to be below 32F water curing is not recommended unless the.

Source: engineeringdiscoveries.com

Source: engineeringdiscoveries.com

Continue reading Top 16 Mistakes. Concrete in cold weather absolutely does need to be curedthe surface can dry out even faster than in warm weather if the concrete is warmer than the air. This is generally the result of an issue with the curing of the concrete and cannot be controlled by the homeowner. If the air is below or expected to go below 40F then use cold weather techniques. Curing has a strong influence on the properties of hardened concrete.

Source: pinterest.com

Source: pinterest.com

For over a century Euclid Chemical has built a reputation on quality products innovation and putting people first. ACI 301 recommends a minimum curing period comparable to concrete attaining 70 of the specified compressive strength. Concrete installation is not nearly as straightforward as it seems. When outdoor temperatures are below 20 degrees Fahrenheit it is best to simply abandon the idea of placing concrete in outdoor locations since hydration stops completely at such temperatures. Everything from the mix design quantity of concrete to purchase site preparation tools weather forecast placement process form removal and curing process need to be.

Source: constructioncost.co

Source: constructioncost.co

Here is advice for curing concrete in freezing temperatures. Our team of industry experts provides service and support that make working with us easy. Euclid Chemical is a world leading manufacturer of specialty chemical products for the concrete and masonry construction industry. If the air is below or expected to go below 40F then use cold weather techniques. Made with SCMs may especially benefit from extended curing.

Source: pinterest.com

Source: pinterest.com

Made with SCMs may especially benefit from extended curing. The need for adequate curing of concrete cannot be overemphasized. Typically this target is obtained within 7 days but it varies from mix to mix. Curing is the maintenance of a satisfactory moisture con-tent and temperature in concrete for a period of time imme-diately following placing and finishing so that the desired properties may develop Fig. ACI 301 recommends a minimum curing period comparable to concrete attaining 70 of the specified compressive strength.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title curing period of concrete slab by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.