Your Diy large concrete slab in sections images are ready. Diy large concrete slab in sections are a topic that is being searched for and liked by netizens today. You can Download the Diy large concrete slab in sections files here. Download all free images.

If you’re looking for diy large concrete slab in sections pictures information related to the diy large concrete slab in sections interest, you have come to the right blog. Our website frequently gives you hints for seeing the maximum quality video and image content, please kindly surf and locate more informative video articles and graphics that fit your interests.

Diy Large Concrete Slab In Sections. Sand also has air in it but it may be a better option for the do-it-yourselfer trying to raise concrete. Then place and compact a 4-inch layer of gravel. 130 and above for heavy duty driveways and larger buildings. Sounds easy but the trick is to de-t e r mine the amount of beam cam- ber upw a r d deflection that will off-set the.

Pouring Concrete How To Prepare And Level Your Site And Soil From concreteideas.com

Pouring Concrete How To Prepare And Level Your Site And Soil From concreteideas.com

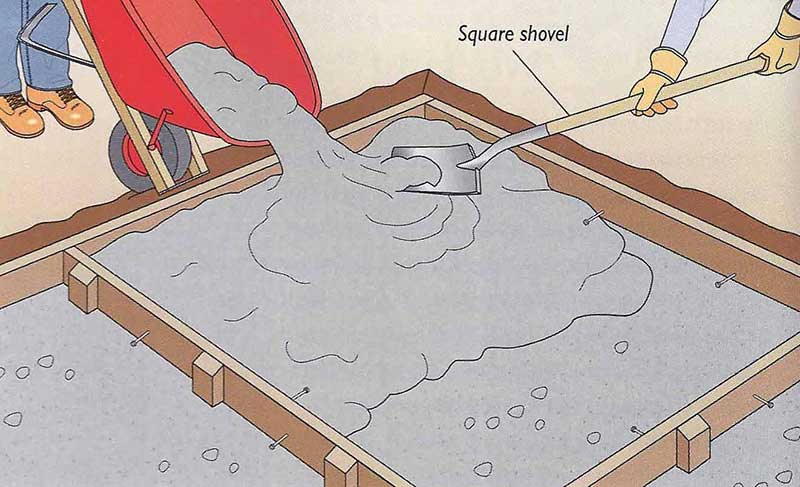

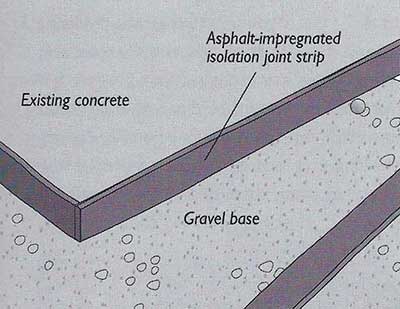

Start by compacting the existing soil. Sounds easy but the trick is to de-t e r mine the amount of beam cam- ber upw a r d deflection that will off-set the. At the end of the leading pour prepare the joint with a little slant and roughen the surface then cover the leading pour with plastic sheets. Even on narrow forms two people will make the work faster and more. Jan 10 2020 - Explore Georges board Concrete Slab on Pinterest. If you cant line up extra help Id recommend dividing the slab into four 7 12-foot-by-7 12-foot sections and pouring each section separately.

Sounds easy but the trick is to de-t e r mine the amount of beam cam- ber upw a r d deflection that will off-set the.

The weight of the concrete slab would then cause the cambered beam to deflect to a level plane at the speci-fied eleva t i o n. 130 and above for heavy duty driveways and larger buildings. The weight of the concrete slab would then cause the cambered beam to deflect to a level plane at the speci-fied eleva t i o n. On large jobs do this batch-by-batch rather than after all the cement is placed. Move a strikeoff example above- a straight wood 2x4 across the form to level the concrete. Pour the concrete in small sections spreading the concrete by moving the chute back and forth and by having the driver pull forward as you go.

Source: twinfallsconcrete.com

Source: twinfallsconcrete.com

Even on narrow forms two people will make the work faster and more. The dowels bars are fairly typical in thicker slabs. Pour in Sections. A concrete slab of uniform thick-ness can be placed by positioning the screeds at the high and low points of the cambered beam. Be sure to make two passes.

Source: familyhandyman.com

Source: familyhandyman.com

Continue pouring until concrete reaches the top of the forms. The dowels bars are fairly typical in thicker slabs. Drag the screed backwards in a back-and-forth sawing motion across the slab to level the surface. The materials are readily available and cheap. Move a strikeoff example above- a straight wood 2x4 across the form to level the concrete.

Source: youtube.com

Source: youtube.com

Start by compacting the existing soil. For very large areas we recommend breaking up the job into multiple pours over several days. Move the board slowly along the form using a side-to-side sawing motion. The materials are readily available and cheap. He says 6 in slab in sections with footers that are 12-15 inches deep and 12 inches wide is the only way to go.

Source: familyhandyman.com

Source: familyhandyman.com

The dowels bars are fairly typical in thicker slabs. Sand also has air in it but it may be a better option for the do-it-yourselfer trying to raise concrete. By far the largest drawback to this old method and the main force for change has been the fact. On large jobs do this batch-by-batch rather than after all the cement is placed. Continue pouring until concrete reaches the top of the forms.

Source: twinfallsconcrete.com

Source: twinfallsconcrete.com

Smaller sections of sunken concrete can be cut out using a wet saw and then lifted out with a crowbar. Plan out the Pour in Advance and Prep all Materials. Smaller sections of sunken concrete can be cut out using a wet saw and then lifted out with a crowbar. We actually already have the footers dug ourselves and were starting on the process but the rain has slowed us up big time so that is why my husband is fed up and just wants us to turn it over to a professional. Even on narrow forms two people will make the work faster and more.

Source: powerblanket.com

Source: powerblanket.com

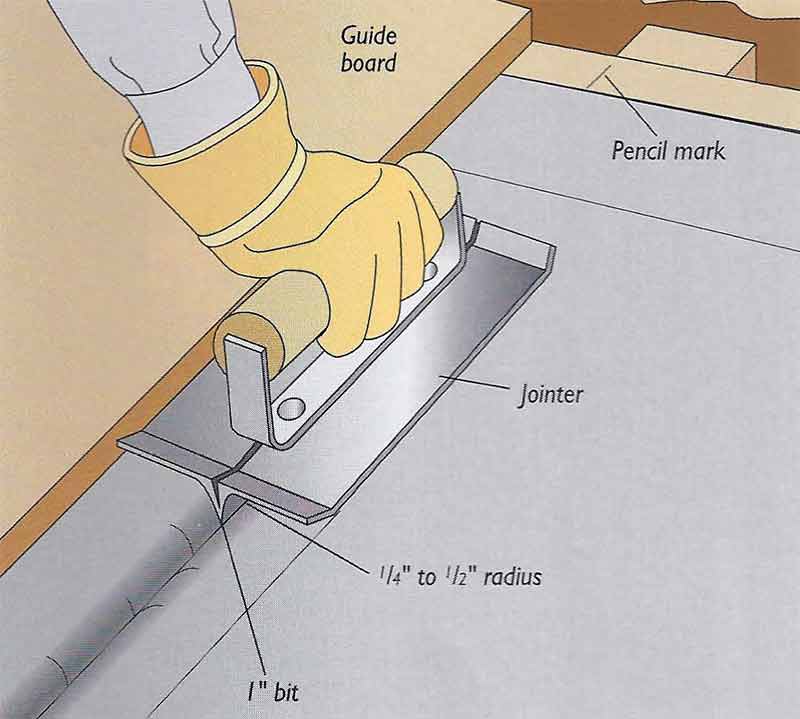

By far the largest drawback to this old method and the main force for change has been the fact. Learn how to pour a concrete slab - DIY with MARSHALLTOWN - YouTube. On the day of the second pour clean the joint with a water wash and wait till the solid concrete appears to be moist but surface dry no hanging water. Start by compacting the existing soil. Striking the DIY concrete patio.

Source: thespruce.com

Source: thespruce.com

Move a strikeoff example above- a straight wood 2x4 across the form to level the concrete. Select a very straight piece of scrap lumber to use as a screedideally wide enough to span the entire slab. Jan 10 2020 - Explore Georges board Concrete Slab on Pinterest. If it is done correctly. The key to a successful pour over a large area is planning as much as possible before you start mixing the leveler.

Source: upgradedhome.com

Source: upgradedhome.com

He says 6 in slab in sections with footers that are 12-15 inches deep and 12 inches wide is the only way to go. The average 4-inch thick concrete slab only weighs 13 of a pound per square inch. Dont fill the whole form or giant sections because the. If it is done correctly. By far the largest drawback to this old method and the main force for change has been the fact.

Source: familyhandyman.com

Source: familyhandyman.com

The average 4-inch thick concrete slab only weighs 13 of a pound per square inch. Hand trowelling this size of a slab in not recommended even for the experienced. At the end of the leading pour prepare the joint with a little slant and roughen the surface then cover the leading pour with plastic sheets. Move a strikeoff example above- a straight wood 2x4 across the form to level the concrete. Be sure to make two passes.

Source: twinfallsconcrete.com

Source: twinfallsconcrete.com

This old concrete expansion jointing method has a few pros and cons. Smaller sections of sunken concrete can be cut out using a wet saw and then lifted out with a crowbar. No special tools or expertise needed to form them. Be sure to make two passes. On large jobs do this batch-by-batch rather than after all the cement is placed.

Source: jlconline.com

Source: jlconline.com

Wide pours would be cut 1 deep across at every 10 foot increments. Move the board slowly along the form using a side-to-side sawing motion. Sounds easy but the trick is to de-t e r mine the amount of beam cam- ber upw a r d deflection that will off-set the. The weight of the concrete slab would then cause the cambered beam to deflect to a level plane at the speci-fied eleva t i o n. A concrete slab of uniform thick-ness can be placed by positioning the screeds at the high and low points of the cambered beam.

Source: doityourself.com

Source: doityourself.com

Wide pours would be cut 1 deep across at every 10 foot increments. Pour concrete into your form and begin consolidating with a concrete hoe or rake. A concrete slab of uniform thick-ness can be placed by positioning the screeds at the high and low points of the cambered beam. Pour the concrete in small sections spreading the concrete by moving the chute back and forth and by having the driver pull forward as you go. On large jobs do this batch-by-batch rather than after all the cement is placed.

Source: youtube.com

Source: youtube.com

Move a strikeoff example above- a straight wood 2x4 across the form to level the concrete. At the end of the leading pour prepare the joint with a little slant and roughen the surface then cover the leading pour with plastic sheets. Hand trowelling this size of a slab in not recommended even for the experienced. Pour concrete into your form and begin consolidating with a concrete hoe or rake. On the day of the second pour clean the joint with a water wash and wait till the solid concrete appears to be moist but surface dry no hanging water.

Source: youtube.com

Source: youtube.com

How to Frame and Pour a Small Concrete Slab DIY - YouTube. Continue pouring until concrete reaches the top of the forms. Once the truck has reached the end of a section spread the concrete out evenly and a touch higher than the form with a concrete placerrake. Hand trowelling this size of a slab in not recommended even for the experienced. Wide pours would be cut 1 deep across at every 10 foot increments.

Source: familyhandyman.com

Source: familyhandyman.com

A concrete slab of uniform thick-ness can be placed by positioning the screeds at the high and low points of the cambered beam. By far the largest drawback to this old method and the main force for change has been the fact. Dont fill the whole form or giant sections because the. A Good Solution for DIYers. He says 6 in slab in sections with footers that are 12-15 inches deep and 12 inches wide is the only way to go.

Source: everything-about-concrete.com

Source: everything-about-concrete.com

Before you begin make sure that you have a well-compacted drainable base for the slab see Pouring a Concrete Patio below. Sounds easy but the trick is to de-t e r mine the amount of beam cam- ber upw a r d deflection that will off-set the. Drag the screed backwards in a back-and-forth sawing motion across the slab to level the surface. Hand trowelling this size of a slab in not recommended even for the experienced. Once mixing is underway you have a.

Source: youtube.com

Source: youtube.com

Select a very straight piece of scrap lumber to use as a screedideally wide enough to span the entire slab. Wide pours would be cut 1 deep across at every 10 foot increments. Plan out the Pour in Advance and Prep all Materials. Jan 10 2020 - Explore Georges board Concrete Slab on Pinterest. On the day of the second pour clean the joint with a water wash and wait till the solid concrete appears to be moist but surface dry no hanging water.

Source: familyhandyman.com

Source: familyhandyman.com

If it is done correctly. Once mixing is underway you have a. On the day of the second pour clean the joint with a water wash and wait till the solid concrete appears to be moist but surface dry no hanging water. Pour concrete into your form and begin consolidating with a concrete hoe or rake. See more ideas about concrete slab concrete concrete diy.

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site good, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title diy large concrete slab in sections by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.