Your Fill gap in concrete floor images are ready in this website. Fill gap in concrete floor are a topic that is being searched for and liked by netizens today. You can Download the Fill gap in concrete floor files here. Find and Download all free vectors.

If you’re looking for fill gap in concrete floor pictures information related to the fill gap in concrete floor topic, you have pay a visit to the right blog. Our website always gives you hints for refferencing the maximum quality video and image content, please kindly search and find more enlightening video articles and graphics that match your interests.

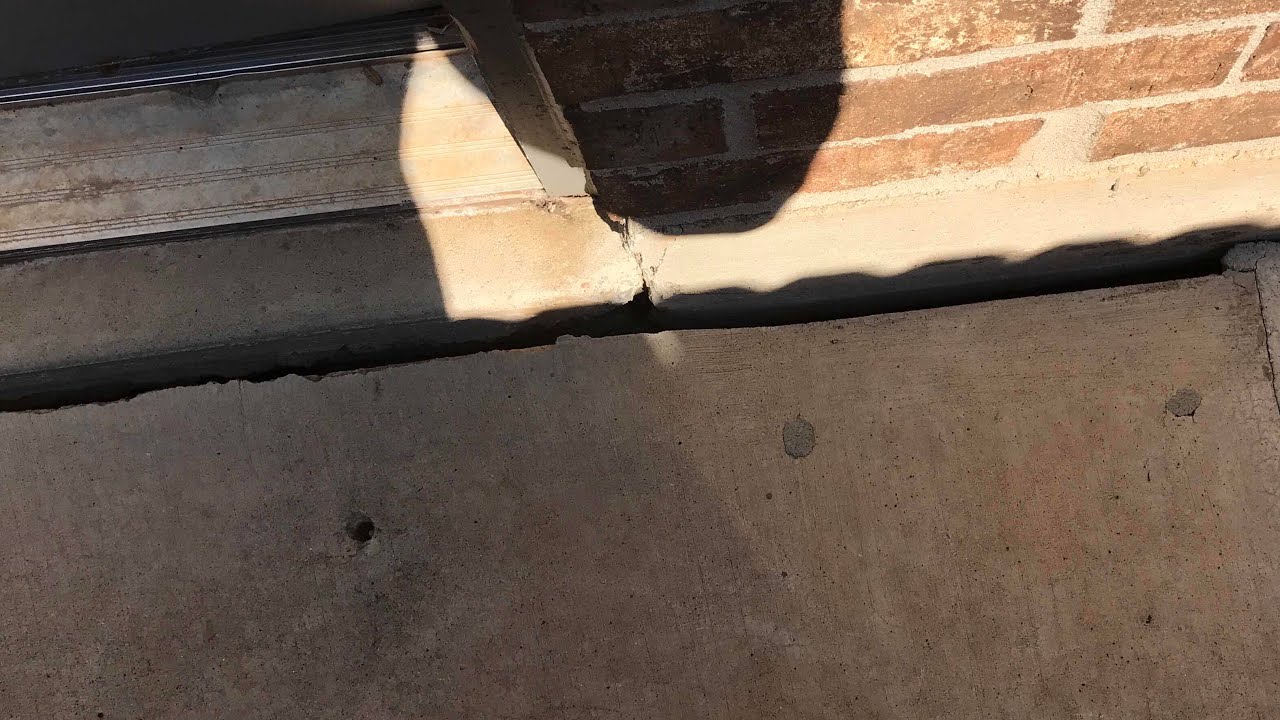

Fill Gap In Concrete Floor. Theres no mixing required its ready to use. The base floor may also be comprised of a mud or structural foundation slab complete with waterproofing and wearing slab with the overall system designed to carry. First apply leveling primer to the concrete and wait 4-5 hours for it to dry before applying the leveling compound. Smooth and repair concrete masonry and wood Smooth and repair concrete masonry and wood surfaces with The Henry 345 Pre-Mixed Patch and Level.

Filling Expansion And Conctraction Joints In A Garage Floor All Garage Floors Garage Floor Expansion Joint Concrete Floors From pinterest.com

Filling Expansion And Conctraction Joints In A Garage Floor All Garage Floors Garage Floor Expansion Joint Concrete Floors From pinterest.com

SIMPLlFIED CONSTRUCTION ESTIMATE 1000 m. 5 Membrane No Gap. List down the materials required. Total cost was less than 200 while a pro would charge 500-1000. Unless the product is labeled as self-leveling it will need to be worked with tools as outlined above. Theres no mixing required its ready to use.

And is suitable for indoor and outdoor use.

FIGURE 1-4 FLOOR PLAN SOLUTION 1. We used 18000-pound screw jacks 4x4 lumber a circular saw power drilldriver and cement blocks. List down the materials required. We got muddy because we were in a dirt crawlspace doing just that crawling. This job took two people one afternoon. Workability is the ability of a fresh plastic concrete mix to fill the formmold properly with the desired work pouring pumping spreading tamping vibration and without reducing the concretes quality.

Source: pinterest.com

Source: pinterest.com

Smooth and repair concrete masonry and wood Smooth and repair concrete masonry and wood surfaces with The Henry 345 Pre-Mixed Patch and Level. Unless the product is labeled as self-leveling it will need to be worked with tools as outlined above. If fixture is above floor surface it is recommended to hand finish concrete around fixture to avoid damage. Theres no mixing required its ready to use. Smooth and repair concrete masonry and wood Smooth and repair concrete masonry and wood surfaces with The Henry 345 Pre-Mixed Patch and Level.

Source: pinterest.com

Source: pinterest.com

Using a self-leveling compound is the easiest way to raise those low spots. This compound can be used to patch non-moving joints in concrete. Cost Time and Skills. Using a self-leveling compound is the easiest way to raise those low spots. Lay the plates in such a way that the treated wood Is.

Source: pinterest.com

Source: pinterest.com

And you only need to fill the gap between the joist and the floor. Before the surface dries fill in any holes or cracks making sure the top of the repair is level with the rest of the concrete surface. List down the materials required. Floor leveling compound is any mix used to fill low areas and imperfections or add as a topcoat to existing flooring. And is suitable for indoor and outdoor use.

Source: pinterest.com

Source: pinterest.com

Once you pour the mixture onto the floor it will move to fill in the lower. Small cracks and fractures can be fixed using a cement. Once you pour the mixture onto the floor it will move to fill in the lower. Unless the product is labeled as self-leveling it will need to be worked with tools as outlined above. Lay the plates in such a way that the treated wood Is.

Source: pinterest.com

Source: pinterest.com

ILLUSTRA TION 1-4 The ground floor of a residential house has an area of 200 square meters. Concrete floor of a parking garage being placed. Cost Time and Skills. Floor Leveling Compound Types and Pros Cons. And you only need to fill the gap between the joist and the floor.

Source: pinterest.com

Source: pinterest.com

Smooth and repair concrete masonry and wood Smooth and repair concrete masonry and wood surfaces with The Henry 345 Pre-Mixed Patch and Level. A treated plate to the concrete floor nailed using the powder actuated gun. FIGURE 1-4 FLOOR PLAN SOLUTION 1. Once you pour the mixture onto the floor it will move to fill in the lower. Small cracks and fractures can be fixed using a cement.

Source: pinterest.com

Source: pinterest.com

Cost Time and Skills. And is suitable for indoor and outdoor use. Ensure rough-in cover is tight to the concrete shield so no concrete seeps into the assembly 6 Pour finish floor slab flush to the top of the rough-in cover. Find the volume of the floor slab. ILLUSTRA TION 1-4 The ground floor of a residential house has an area of 200 square meters.

Source: pinterest.com

Source: pinterest.com

Before the surface dries fill in any holes or cracks making sure the top of the repair is level with the rest of the concrete surface. Floor leveling compound is any mix used to fill low areas and imperfections or add as a topcoat to existing flooring. FIGURE 1-4 FLOOR PLAN SOLUTION 1. Ensure rough-in cover is tight to the concrete shield so no concrete seeps into the assembly 6 Pour finish floor slab flush to the top of the rough-in cover. Theres no mixing required its ready to use.

Source: pinterest.com

Source: pinterest.com

A treated plate to the concrete floor nailed using the powder actuated gun. FIGURE 1-4 FLOOR PLAN SOLUTION 1. Pouring and smoothing out concrete at Palisades Park in Washington DC. ILLUSTRA TION 1-4 The ground floor of a residential house has an area of 200 square meters. Total cost was less than 200 while a pro would charge 500-1000.

Source: pinterest.com

Source: pinterest.com

And a regular plate on top of that. Total cost was less than 200 while a pro would charge 500-1000. One container will cover up to 5 sq. And a regular plate on top of that. And you only need to fill the gap between the joist and the floor.

Source: gr.pinterest.com

Source: gr.pinterest.com

Small cracks and fractures can be fixed using a cement. Lay the plates in such a way that the treated wood Is. FIGURE 1-4 FLOOR PLAN SOLUTION 1. Theres no mixing required its ready to use. The base floor within a building may simply be a cast-in-place concrete slab-on-grade with limited design considerations for structural support or environmental control functions.

Source: pinterest.com

Source: pinterest.com

Workability is the ability of a fresh plastic concrete mix to fill the formmold properly with the desired work pouring pumping spreading tamping vibration and without reducing the concretes quality. Workability is the ability of a fresh plastic concrete mix to fill the formmold properly with the desired work pouring pumping spreading tamping vibration and without reducing the concretes quality. Ensure rough-in cover is tight to the concrete shield so no concrete seeps into the assembly 6 Pour finish floor slab flush to the top of the rough-in cover. SIMPLlFIED CONSTRUCTION ESTIMATE 1000 m. We used 18000-pound screw jacks 4x4 lumber a circular saw power drilldriver and cement blocks.

Source: pinterest.com

Source: pinterest.com

We used 18000-pound screw jacks 4x4 lumber a circular saw power drilldriver and cement blocks. Concrete floor of a parking garage being placed. 5 Membrane No Gap. Once you pour the mixture onto the floor it will move to fill in the lower. One container will cover up to 5 sq.

Source: pinterest.com

Source: pinterest.com

SIMPLlFIED CONSTRUCTION ESTIMATE 1000 m. Floor Leveling Compound Types and Pros Cons. We got muddy because we were in a dirt crawlspace doing just that crawling. Follow the manufacturers instructions for preparing the leveling compound. We used 18000-pound screw jacks 4x4 lumber a circular saw power drilldriver and cement blocks.

Source: pinterest.com

Source: pinterest.com

Floor Leveling Compound Types and Pros Cons. The plan specify 4 inches thick concrete floor on fill using class C concrete. Unless the product is labeled as self-leveling it will need to be worked with tools as outlined above. And a regular plate on top of that. We got muddy because we were in a dirt crawlspace doing just that crawling.

Source: pinterest.com

Source: pinterest.com

If fixture is above floor surface it is recommended to hand finish concrete around fixture to avoid damage. Find the volume of the floor slab. Using a self-leveling compound is the easiest way to raise those low spots. We used 18000-pound screw jacks 4x4 lumber a circular saw power drilldriver and cement blocks. One container will cover up to 5 sq.

Source: pinterest.com

Source: pinterest.com

A treated plate to the concrete floor nailed using the powder actuated gun. SIMPLlFIED CONSTRUCTION ESTIMATE 1000 m. Floor Leveling Compound Types and Pros Cons. FIGURE 1-4 FLOOR PLAN SOLUTION 1. Total cost was less than 200 while a pro would charge 500-1000.

Source: hu.pinterest.com

Source: hu.pinterest.com

FIGURE 1-4 FLOOR PLAN SOLUTION 1. Fill in any cracks or imperfections in the surface. First apply leveling primer to the concrete and wait 4-5 hours for it to dry before applying the leveling compound. Cost Time and Skills. We got muddy because we were in a dirt crawlspace doing just that crawling.

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site convienient, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title fill gap in concrete floor by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.