Your How to make cement clinker images are ready in this website. How to make cement clinker are a topic that is being searched for and liked by netizens today. You can Download the How to make cement clinker files here. Download all free photos.

If you’re looking for how to make cement clinker pictures information related to the how to make cement clinker interest, you have come to the ideal blog. Our website frequently provides you with suggestions for viewing the maximum quality video and image content, please kindly surf and locate more informative video articles and images that fit your interests.

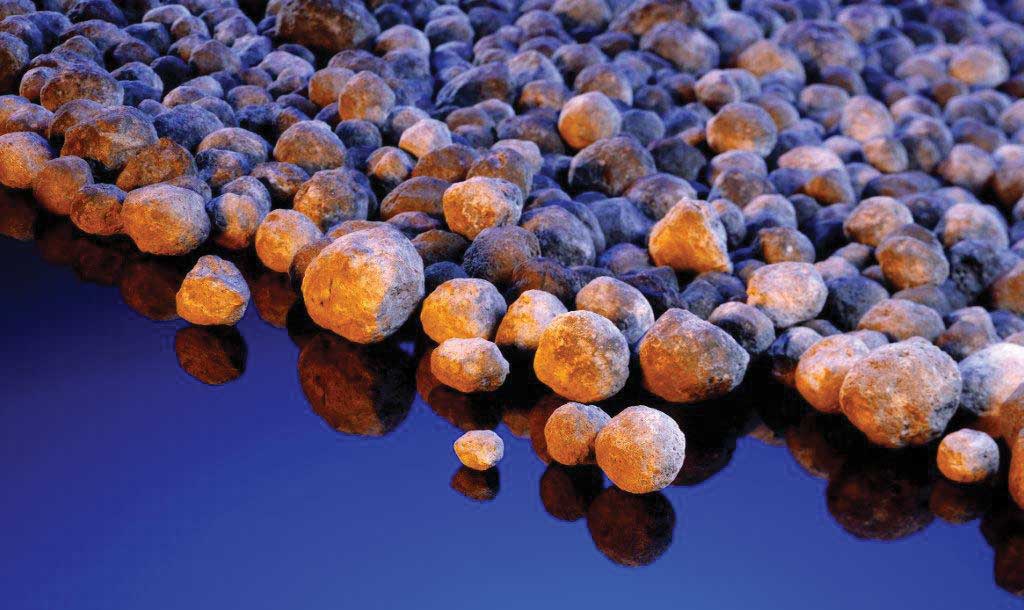

How To Make Cement Clinker. Then Grind the Clinker with Gypsum to make Cement. To make cement you have to first make clinker. Grinding a mixture of limestone and clay or shale to make a fine rawmix see Rawmill. Portland cement clinker is nodules diameters 525 mm of sintered material produced by heating a homogeneous mixture of raw materials in a kiln to a sintering temperature of approximately 1450 C for modern cements.

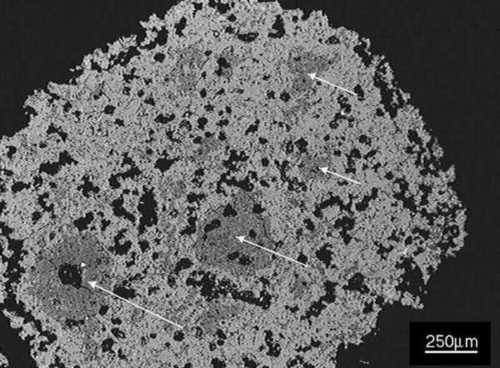

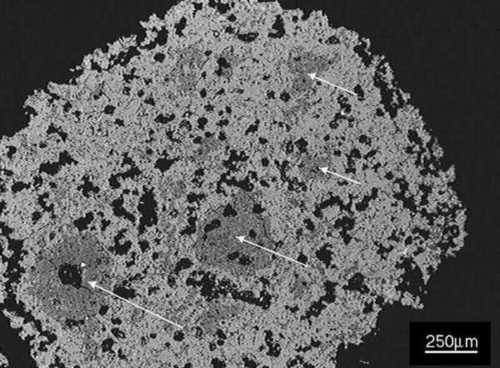

Portland Cement Clinker From understanding-cement.com

Portland Cement Clinker From understanding-cement.com

Portland cement clinker is nodules diameters 525 mm of sintered material produced by heating a homogeneous mixture of raw materials in a kiln to a sintering temperature of approximately 1450 C for modern cements. Limestone is extracted from Mines. Ad We Offer a Wide Variety of Concrete Tools and Supplies at Affordable Prices. On making 1 ton of cement how many clinker in ton needed. The result is called clinker which are rounded nodules between 1mm and 25mm across. 6-47 2CaOSiO 2.

After the raw material is preheated and precalcined the next step is clinker manufacturing.

How many lime stone requird totonn clinker Limestone. So a plant has to first make Clinker. Ad We Offer a Wide Variety of Concrete Tools and Supplies at Affordable Prices. 22 rows The production of clinker involves the feeding of the raw meal into the kiln where. Clinker calcination is the most crucial part of the whole process of cement manufacturing. How many tons of limesandstone does it take to produce one ton of.

Source: datis-inc.com

Source: datis-inc.com

After the raw material is preheated and precalcined the next step is clinker manufacturing. Finally add water as needed. The crushed rock is combined with other ingredients such as iron ore or fly ash and ground mixed and fed to a cement kiln. The cement kiln heats all the ingredients to about 2700 degrees Fahrenheit in huge cylindrical steel rotary kilns lined with special firebrick. 37-72 of 3CaOSiO 2.

Source: lowcarboneconomy.cembureau.eu

Source: lowcarboneconomy.cembureau.eu

So a plant has to first make Clinker. Portland cement clinker is nodules diameters 525 mm of sintered material produced by heating a homogeneous mixture of raw materials in a kiln to a sintering temperature of approximately 1450 C for modern cements. It is produced by heating limestone and clay to the point of liquefaction at about 1400C-1500C in the rotary kiln. So a plant has to first make Clinker. The cement kiln heats all the ingredients to about 2700 degrees Fahrenheit in huge cylindrical steel rotary kilns lined with special firebrick.

Source: understanding-cement.com

Source: understanding-cement.com

Clinker calcination is the most crucial part of the whole process of cement manufacturing. Grinding the resulting clinker to make cement see Cement mill. Portland cement clinker is a dark grey nodular material made by heating ground limestone and clay at a temperature of about 1400 C - 1500 C. Answer 1 of 2. Grinding a mixture of limestone and clay or shale to make a fine rawmix see Rawmill.

To make cement you have to first make clinker. Portland cement clinker is the material that gets ground up possibly with gypsum and other small quantities of material to become Portland cement. Portland cement clinker is a dark grey nodular material made by heating ground limesandstone and clay at a temperature of Portland cement clinker contains four. Limestone is mixed with clay soil and iron ore to make clinker which is then ground with gypsum and limestone again to make cement. At this stage ground raw materials will be sent into the cement kiln and be heated at a high temperature to produce chemical reactions with each other eventually forming clinker.

Source: sciencedirect.com

Source: sciencedirect.com

As the temperature of the material increases the mineral becomes a liquid phase and reacts to form a large amount clinker. The powdered cement is then mixed with water and aggregates to form concrete that is used in construction. Ad We Offer a Wide Variety of Concrete Tools and Supplies at Affordable Prices. The stone should be between a 12 inch to an inch with rounded sides. Grinding a mixture of limestone and clay or shale to make a fine rawmix see Rawmill.

Source: amootiranian.com

Source: amootiranian.com

Answer 1 of 2. Then Grind the Clinker with Gypsum to make Cement. Top two countries China and India make up about two-thirds of total cement production in the world. Grinding the resulting clinker to make cement see Cement mill. Portland cement clinker overview Understanding Cement.

The crushed rock is combined with other ingredients such as iron ore or fly ash and ground mixed and fed to a cement kiln. Those granules are the. The powdered cement is then mixed with water and aggregates to form concrete that is used in construction. A typical process of manufacture consists of three stages. Portland cement clinker is a dark grey nodular material made by heating ground limesandstone and clay at a temperature of Portland cement clinker contains four.

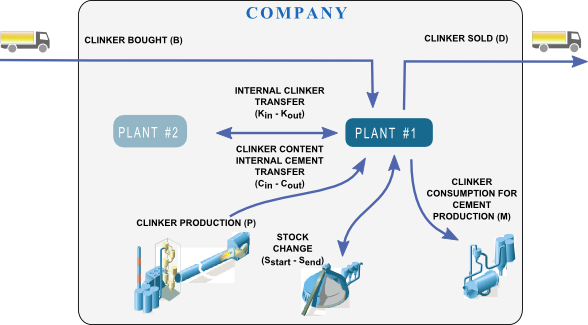

Source: lowcarboneconomy.cembureau.eu

Source: lowcarboneconomy.cembureau.eu

Browse Our Extensive Selection of Concrete Tools Equipment Accessories Now. At this stage ground raw materials will be sent into the cement kiln and be heated at a high temperature to produce chemical reactions with each other eventually forming clinker. 37-72 of 3CaOSiO 2. Limestone is the pre-requisite to make Clinker. Two are silicate cement their cement raw materials include calcareous materials and salic materials all materials are calcined by cement rotary kiln into cement clinker add gypsum and admixture into clinker which is grounded into white cement or Portland cement.

Source: dir.indiamart.com

Source: dir.indiamart.com

What are the steps of cement clinker production. At this stage ground raw materials will be sent into the cement kiln and be heated at a high temperature to produce chemical reactions with each other eventually forming clinker. 22 rows The production of clinker involves the feeding of the raw meal into the kiln where. How many lime stone requird totonn clinker Limestone. The nodules are ground up to a fine powder to produce cement with a small amount of gypsum added to control the setting properties.

Source: cement-co2-protocol.org

Source: cement-co2-protocol.org

The crushed rock is combined with other ingredients such as iron ore or fly ash and ground mixed and fed to a cement kiln. Portland cement clinker is nodules diameters 525 mm of sintered material produced by heating a homogeneous mixture of raw materials in a kiln to a sintering temperature of approximately 1450 C for modern cements. Then Grind the Clinker with Gypsum to make Cement. Limestone is the pre-requisite to make Clinker. In the rotary kiln the carbonate is further rapidly precalcined and a series of solid phase reactions occur to form minerals in the cement clinker.

Source: azintrade.com

Source: azintrade.com

The basic formula to make concrete is 1 part cement 2 parts sand and 3 parts aggregate by volume. Answer 1 of 2. Ad We Offer a Wide Variety of Concrete Tools and Supplies at Affordable Prices. Those granules are the. Portland cement clinker is the material that gets ground up possibly with gypsum and other small quantities of material to become Portland cement.

Source: lowcarboneconomy.cembureau.eu

Source: lowcarboneconomy.cembureau.eu

The basic formula to make concrete is 1 part cement 2 parts sand and 3 parts aggregate by volume. After the raw material is preheated and precalcined the next step is clinker manufacturing. Portland cement clinker is a dark grey nodular material made by heating ground limestone and clay at a temperature of about 1400 C - 1500 C. China is the leader on both cement production and clinker production accounting for more than 50 of total production. The production and clinker capacity of countries in 2015 and 2016 are summarized in Table 1 9.

Source: ceramics.org

Source: ceramics.org

The powdered cement is then mixed with water and aggregates to form concrete that is used in construction. The basic formula to make concrete is 1 part cement 2 parts sand and 3 parts aggregate by volume. Portland cement clinker overview Understanding Cement. A typical process of manufacture consists of three stages. Grinding a mixture of limestone and clay or shale to make a fine rawmix see Rawmill.

Source: wikiwand.com

Source: wikiwand.com

Those granules are the. Those granules are the. It is produced by heating limestone and clay to the point of liquefaction at about 1400C-1500C in the rotary kiln. Top two countries China and India make up about two-thirds of total cement production in the world. 4 The composition of a typical good quality clinker for general use.

Source: cementplantequipment.com

Source: cementplantequipment.com

How many tons of limesandstone does it take to produce one ton of. 4 The composition of a typical good quality clinker for general use. The result is called clinker which are rounded nodules between 1mm and 25mm across. Ad We Offer a Wide Variety of Concrete Tools and Supplies at Affordable Prices. The powdered cement is then mixed with water and aggregates to form concrete that is used in construction.

Source: arijco.com

Source: arijco.com

China is the leader on both cement production and clinker production accounting for more than 50 of total production. China is the leader on both cement production and clinker production accounting for more than 50 of total production. The result is called clinker which are rounded nodules between 1mm and 25mm across. The powdered cement is then mixed with water and aggregates to form concrete that is used in construction. The crushed rock is combined with other ingredients such as iron ore or fly ash and ground mixed and fed to a cement kiln.

Source: minera-group.com

Source: minera-group.com

The production and clinker capacity of countries in 2015 and 2016 are summarized in Table 1 9. Limestone clay bauxite and iron ore sand in specific proportions are heated in a rotating kiln at 2770 Fahrenheit 1400 Celsius until they begin to form cinder lumps which are also known as cement clinkers. The production and clinker capacity of countries in 2015 and 2016 are summarized in Table 1 9. Clinker is in the form of rounded granules typically 3 to 25mm diameter. In the rotary kiln the carbonate is further rapidly precalcined and a series of solid phase reactions occur to form minerals in the cement clinker.

Source: understanding-cement.com

Source: understanding-cement.com

The clinker is ground to a fine powder in a cement mill and mixed with gypsum to create cement. The stone should be between a 12 inch to an inch with rounded sides. Portland cement clinker is a dark grey nodular material made by heating ground limestone and clay at a temperature of about 1400 C - 1500 C. What are the steps of cement clinker production. Clinker when added with gypsum to control the setting properties of cement and ensure compressive strength and ground finely produces cement.

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site good, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title how to make cement clinker by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.