Your Polished concrete slab specifications images are ready. Polished concrete slab specifications are a topic that is being searched for and liked by netizens now. You can Find and Download the Polished concrete slab specifications files here. Find and Download all free images.

If you’re searching for polished concrete slab specifications images information related to the polished concrete slab specifications topic, you have visit the right blog. Our website frequently gives you suggestions for seeing the maximum quality video and picture content, please kindly surf and locate more informative video content and images that match your interests.

Polished Concrete Slab Specifications. Affect installation of polished concrete floor system. 24 For curing materials and methods see SB12U. We recommend 4000 psi for best results but a minimum of 3500 psi is required. Strength as called for on the drawing and proportioning 23 For joints in floors on earth see SB15U.

Lazenby Polished Concrete Technical Drawings From lazenby.co.uk

Lazenby Polished Concrete Technical Drawings From lazenby.co.uk

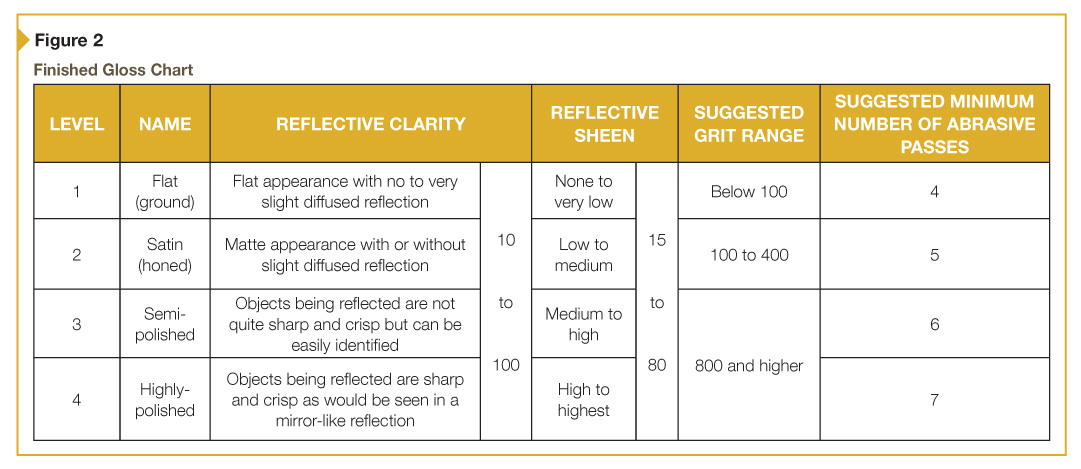

Also care has to be taken when laying the Concrete eg- Screed Marks Foot Prints etc. Smoother polished concrete surfaces can be achieved through extended honing using progressively finer abrasives finer grinding grit headspads to impart a lustre to the concrete surface. A mandatory requirements checklist and an optional requirements checklist are provided to assist the ArchitectEngineer in supplementing the provisions of this Specification. Strength as called for on the drawing and proportioning 23 For joints in floors on earth see SB15U. Local contractors are ready to help. Design and specification considerations.

The foundation of a beautiful floor starts with the flatwork.

Looking straight down the floor will clearly reflect. ASTM C171 Specifications for Sheet Materials for Curing Concrete 4. This is a Reference Specification that the ArchitectEngineer can apply to any construction project involving polished concrete slab finishes by citing it in the Project Specifications. Minimum of 32mpa concrete with 100 cement content no reduction of cement for additives such as slags etc no water to be added on site during concrete placement. The new Specification for Polished Concrete Slab Finishes ACI 3101 provides minimum standards that can be applied to any polished concrete slab finishes. 22 Specifications SBIU and SB6U apply to and are a 36 Concrete shall be the minimum compressive part of this specification.

Source: constructionspecifier.com

Source: constructionspecifier.com

A 93000-m 2 1 million-sf industrial slab pre-qualifies bidders based on the scope of work and the equipment that is involved. Shall conform to SB6U. Need help with cement work. Provisions governing testing evaluation and acceptance of polished concrete slab finishe s are included. Because of the risk of pushing the aggregate down too far.

Source: dmafloors.com

Source: dmafloors.com

Minimum of 32mpa concrete with 100 cement content no reduction of cement for additives such as slags etc no water to be added on site during concrete placement. Retain or delete article below to suit project requirements and specifiers practice integrated with 03 30 00 Cast- in-Place Concrete section. Upgraded mesh to SL 82 or 92. At a distance of 30 to 50 feet the floor will clearly reflect from side and overhead lighting and achieve gloss meter readings of 41 to 55. This Data Sheet provides suggested clauses for inclusion in specifications for honed concrete.

Source: lazenby.co.uk

Source: lazenby.co.uk

Smoother polished concrete surfaces can be achieved through extended honing using progressively finer abrasives finer grinding grit headspads to impart a lustre to the concrete surface. ASTM C171 Specifications for Sheet Materials for Curing Concrete 4. Provisions governing testing evaluation and acceptance of polished concrete slab finishe s are included. 24 For curing materials and methods see SB12U. Because of the risk of pushing the aggregate down too far.

Source: lazenby.co.uk

Source: lazenby.co.uk

Design and specification considerations. You may be thinking the hardened concrete properties belong in the concrete placement specification and they should be. However all concrete contractors believe they can place and finish 90 to 450 m 2 1000 to 5000 sf of concrete to be polished. A 93000-m 2 1 million-sf industrial slab pre-qualifies bidders based on the scope of work and the equipment that is involved. Polished Concrete Level 2 Medium Gloss.

Source: buildinganddecor.co.za

Source: buildinganddecor.co.za

Provisions governing testing evaluation and acceptance of polished concrete slab finishe s are included. It should also be placed in the polished concrete specification. A 1 meter overlap to the polished concrete. 22 Specifications SBIU and SB6U apply to and are a 36 Concrete shall be the minimum compressive part of this specification. ASTM C881 Specification for Epoxy-Resin-Base Bonding Systems for Concrete 6.

Source: tr.pinterest.com

Source: tr.pinterest.com

A mandatory requirements checklist and an optional requirements checklist are provided to assist the ArchitectEngineer in supplementing the provisions of this Specification. Minimum of 32mpa concrete with 100 cement content no reduction of cement for additives such as slags etc no water to be added on site during concrete placement. The new Specification for Polished Concrete Slab Finishes ACI 3101 provides minimum standards that can be applied to any polished concrete slab finishes. The same concrete grade should be used in the slab dont pour 25Mpa in the polished area and 20Mpa grey concrete to the balance. Bathroomwet area 40mm stepdowns are recommended to be 100mm inside plan.

Source: lazenby.co.uk

Source: lazenby.co.uk

A mandatory requirements checklist and an optional requirements checklist are provided to assist the ArchitectEngineer in supplementing the provisions of this Specification. There are not published standards for polished concrete but it is generally agreed that the concrete must be polished through the sequence of disks ending with 1800-3500 grit diamonds to be considered polished concrete. Strike off and laser screed slabs. Provisions governing testing evaluation and acceptance of polished concrete slab finishe s are included. ASTM C150 Specification for Portland Cement 3.

Source: lazenby.co.uk

Source: lazenby.co.uk

Always pour the polished concrete section first to avoid contamination. There are not published standards for polished concrete but it is generally agreed that the concrete must be polished through the sequence of disks ending with 1800-3500 grit diamonds to be considered polished concrete. Bathroomwet area 40mm stepdowns are recommended to be 100mm inside plan. Smoother polished concrete surfaces can be achieved through extended honing using progressively finer abrasives finer grinding grit headspads to impart a lustre to the concrete surface. CONCRETE POLISHING SYSTEM SPECIFICATIONS 1.

Source: ecoflor.co.uk

Source: ecoflor.co.uk

Slabs and flatwork shall be placed and finished monolithically. It should also be placed in the polished concrete specification. We recommend 4000 psi for best results but a minimum of 3500 psi is required. Concrete is not considered well polished before 800 grit and it is normally finished to either the 800 1500 or 3000 grit level. The first section of this Specification covers general requirem ents for polished concrete slab finishes.

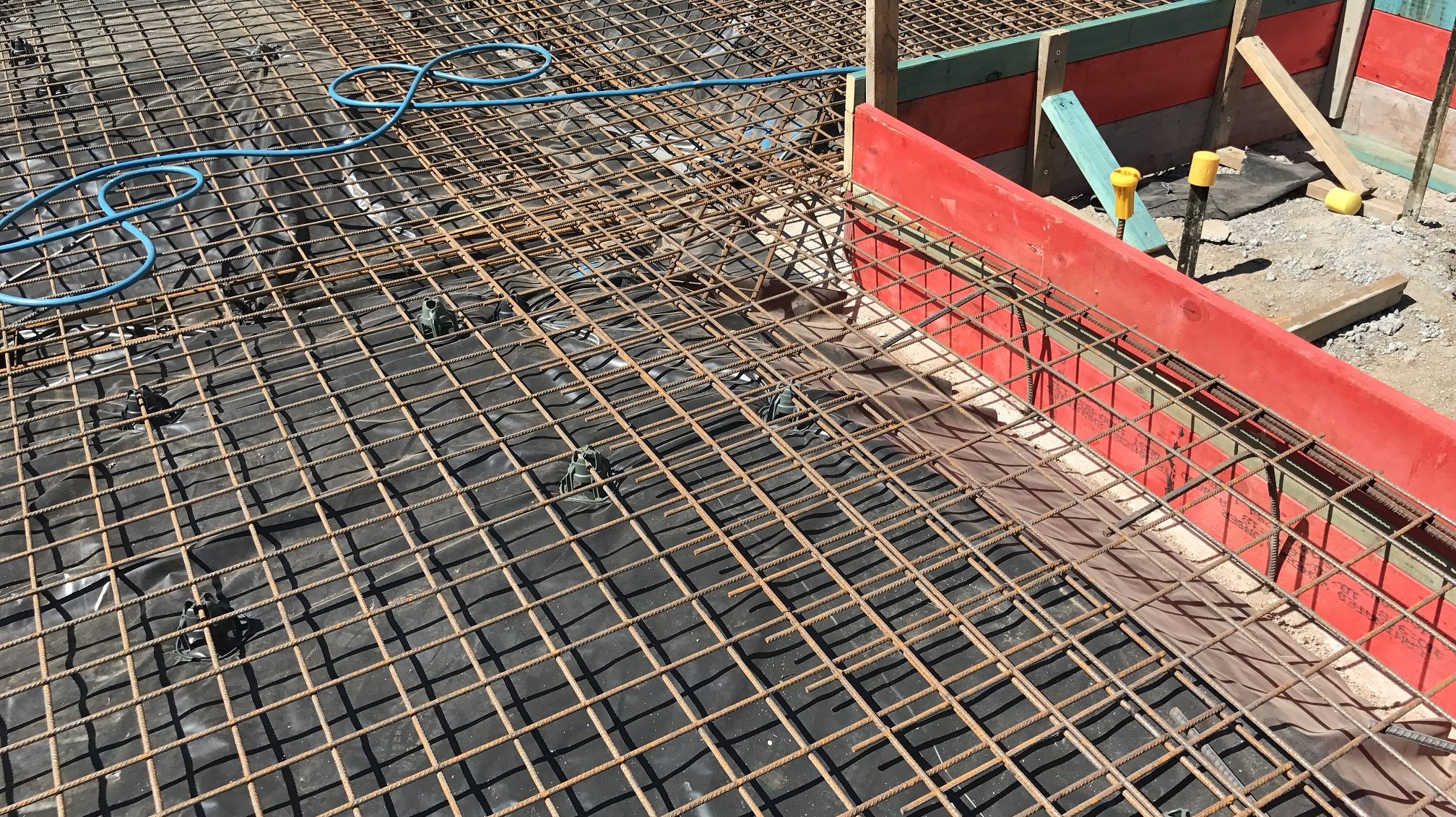

ASTM C309 Specification for Liquid Membrane-Forming Compounds for Curing Concrete 5. A polished concrete topping slab can be used to also encase embedded hydronic heating systems. Design and specification considerations. However all concrete contractors believe they can place and finish 90 to 450 m 2 1000 to 5000 sf of concrete to be polished. 100mm thick slab.

Source: cornellengineers.com.au

Source: cornellengineers.com.au

Shall conform to SB6U. The foundation of a beautiful floor starts with the flatwork. ASTM C309 Specification for Liquid Membrane-Forming Compounds for Curing Concrete 5. A polished concrete topping slab can be used to also encase embedded hydronic heating systems. Shall conform to SB6U.

Source: continuingeducation.bnpmedia.com

Source: continuingeducation.bnpmedia.com

Ad The Art of Polished Concrete. 22 Specifications SBIU and SB6U apply to and are a 36 Concrete shall be the minimum compressive part of this specification. Free of debris and excessive dirt dust clay and mud. A 1 meter overlap to the polished concrete. ASTM C33 Specification for Concrete Aggregates 2.

Source: lazenby.co.uk

Source: lazenby.co.uk

A 93000-m 2 1 million-sf industrial slab pre-qualifies bidders based on the scope of work and the equipment that is involved. No vibrator is to be used in the top 100 mm of the Concrete slab so to minimise areas with no stone. Local contractors are ready to help. However all concrete contractors believe they can place and finish 90 to 450 m 2 1000 to 5000 sf of concrete to be polished. Contractors can believe this but the specifier should not.

Source: lazenby.co.uk

Source: lazenby.co.uk

NOTE TO SPECIFIER Article below summarizes minimum performance requirements of existing concrete floor prior to receiving floor finishing and polishing process. A 93000-m 2 1 million-sf industrial slab pre-qualifies bidders based on the scope of work and the equipment that is involved. Upgraded mesh to SL 82 or 92. A polished concrete topping slab can be used to also encase embedded hydronic heating systems. You may be thinking the hardened concrete properties belong in the concrete placement specification and they should be.

Source: continuingeducation.bnpmedia.com

Source: continuingeducation.bnpmedia.com

37 Concrete seaier shall be a butadiene-styrene con-. The second section covers requirements for products and equipment and the third section covers construction requirements. There are not published standards for polished concrete but it is generally agreed that the concrete must be polished through the sequence of disks ending with 1800-3500 grit diamonds to be considered polished concrete. Building owners designers and residentstenants are increasingly using exposed polished concrete floors for a variety of interior spaces because of its pleasing aesthetics. New or existing floor.

Source: terrazzomasters.com

Source: terrazzomasters.com

However all concrete contractors believe they can place and finish 90 to 450 m 2 1000 to 5000 sf of concrete to be polished. Retain or delete article below to suit project requirements and specifiers practice integrated with 03 30 00 Cast- in-Place Concrete section. Strike off and laser screed slabs. However all concrete contractors believe they can place and finish 90 to 450 m 2 1000 to 5000 sf of concrete to be polished. Smoother polished concrete surfaces can be achieved through extended honing using progressively finer abrasives finer grinding grit headspads to impart a lustre to the concrete surface.

Source: aicoat.com

Source: aicoat.com

NOTE TO SPECIFIER Article below summarizes minimum performance requirements of existing concrete floor prior to receiving floor finishing and polishing process. Shall conform to SB6U. ASTM C309 Specification for Liquid Membrane-Forming Compounds for Curing Concrete 5. The same admixtures shrinkage reducers should be used in all concrete in the slab. 37 Concrete seaier shall be a butadiene-styrene con-.

Source: aicoat.com

Source: aicoat.com

Shall conform to SB6U. Polished Concrete Level 2 Medium Gloss. New or existing floor. Smoother polished concrete surfaces can be achieved through extended honing using progressively finer abrasives finer grinding grit headspads to impart a lustre to the concrete surface. ASTM C150 Specification for Portland Cement 3.

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site convienient, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title polished concrete slab specifications by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.